Dry Oven for Persptrometer solution|thermoline drying oven specifications : manufacture After 30 min take out the specimen and wash with water., then dry in the air oven at temperature at 50 ° C. Take out the soap solution from the laundrometer and compare the same with fresh soap solution and observe for colour bleeding; Compare the tested specimen with fresh sample and observe the colour fastness to washing with the help of .

Set up, manage, and control your Google Nest, Google Wifi, .

{plog:ftitle_list}

Resultado da The Mucalol Live Polemica Video caused a stir when a streamer found themselves in an unexpected intimate situation during a live broadcast. This article takes a closer look at what happened in the video, the reactions and comments from viewers, and an interview with Annie Knight, who claims to .

Temperature: room temperature +10 °C ~ 250 °C. Temperature fluctuation: ± 0.5 °C. Drying time: 0 ~ 99.9h. Working size: 340 x 320 x 320mm. Power: AC220V 50HZ 500W. Power consumption: 750W. Dimension: 480 x 480 x 620mm. Weight: 23Kg.The IKA OVEN 125 basic dry covers applications in industry, schools / universities, research, quality control and science. Fast heat up times and a precise temperature control guarantee reproducible test results. A special . 1. Precision and Reproducibility: Drying ovens offer precise and repeatable drying conditions, allowing researchers and manufacturers to achieve consistent results in their experiments and production processes. 2. Time .IKA OVEN 125 control - dry Drying oven The models in the IKA Oven 125 dry series are powerful drying cabinets for temperature regulation, drying, ageing and heating tasks. Rapid heating and exact temperature regulation guarantee .

Ventilation: Moisture is expelled from the oven through exhaust vents. Key Features of Drying Ovens. When selecting a drying oven, it’s essential to consider the features that will best suit your specific applications. Here are some key features to look for: 1.Temperature Range: Ensure the oven can reach the temperatures required for your .After 30 min take out the specimen and wash with water., then dry in the air oven at temperature at 50 ° C. Take out the soap solution from the laundrometer and compare the same with fresh soap solution and observe for colour bleeding; Compare the tested specimen with fresh sample and observe the colour fastness to washing with the help of .

The Incubator/Oven Model HX30 has a capacity of up to four (4) Perspirometer units. Open out the specimen by breaking the stitching on all but one of the short sides and dry by hanging in the air at a temperature not exceeding 60°C, with the three parts in contact only at the line of stitching.

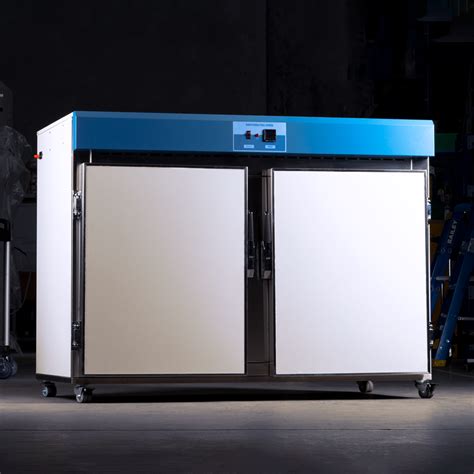

Drying Ovens. Our industrial dry heat ovens are manufactured by Gruenberg and Blue M to remove moisture from products. Both brands offer a wide range with drying capabilities and high temperature ranges, you are sure to find the right fit. Drying ovens, or dry heat ovens, are used to remove moisture content from coatings and various substrates."A Perfect Solution." - Lab Manager. Traditionally, those in the lab animal science field have used autoclaves, which employ steam, vacuum, and pressure, to sterilize their tools and the cages that house the animals they study. . Gruenberg is a leader in dry heat sterilization technology, with advanced dry heat oven sterilizers that eliminate .Lab Drying Oven Drying Oven Machine for Labaratory, Find Details and Price about Aatcc15 ISO105 Aataa107 Aatcc106 Dry Oven for Perspirometer from Lab Drying Oven Drying Oven Machine for Labaratory - SKZ International Co., Ltd.Non-stick Teflon racks allow masks to be placed directly on the rack for easy preparation. A simple interface automatically sets the oven to 165˚F, and can be manually adjusted as well. The AirFlow Oven heats masks in 3-5 minutes and is the fastest oven available today. Thermoplastics come out of the oven completely dry and ready to be formed.

treated in two different solutions of artificial perspirant – one alkaline and one acidic. Up to 20 alkaline or acidic specimens, each in contact with a piece of multifibre and separated by acrylic plates, are placed inside a Perspirometer. The Perspirometer is placed in .BMT Venticell Forced Air Dry-Heat Ovens are equipped with patented system of forced air convection to meet the demands of diverse industries for top-quality drying components, non-flammable materials, glass ware, and more. Venticell dry-heat ovens are designed to provide a precise temperature profile for all drying and heating processes. Uses of drying oven A heating or drying oven can be seen in several applications as follows. In pharmaceutical, food (such as rambutan drying) and agriculture industries, environmental technology, and forestry for determining dry content and humidity content.Oven drying method is key to it like the determination of the moisture content of milk powderPerspirometer always equipped with a kit of instruments including: Perspirometer YG(B)631, Perspiration Oven YG(B)902G. And advanced YG(B)632 is also strongly recommended for automatic immersion of test samples during the perspiration staining color fastness testing.

PURPOSE To determine the resistance of the colour of textiles to the action of artificial human sweat. EQUIPMENT • Chemicals for the alkaline solution - see preparation of solutions. • Chemicals for the acid solution - see preparation of solutions. • Distilled water, grade 3 • Scale • PH-meter • 2 Measuring jugs holding at least 1 litre • Perspirometer • 11 acrylic-resin or .

A Drying Oven is a product used for drying various materials or samples in a controlled environment. Its key features include precise temperature control, uniform airflow distribution, and adjustable shelves for flexible usage. The benefits of a Drying Oven include efficient and consistent drying, preservation of sample integrity, and time-saving operation. Its unique .The Manosplint Dry Heat Oven is a new and innovative device built using high quality stainless steel and aluminum material, providing a high level of heat isolation and temperature stability. . Heating Solutions (5) Dry Heat Oven; . Hot air oven. It is a common form of dry heat sterilization used in the workplace. It is basically an oven that can hold several objects. It is closed for a specific timeframe to sterilize the objects inside it. The desired temperature .The Dry Oven, a streamlined microcontroller system, boasts impressive capacities of 25 liters, 50 liters, and 105 liters. This efficient device thrives in an operational ambient temperature range of 50°C to 200°C, making it versatile for various applications. Its user-friendly interface includes a digital display that provides real-time .

Static applications such as dry heat ovens provide a reliable method for sterilizing surgical instruments, glass vials, and other medical devices through the even distribution of hot air. This uniform temperature distribution is essential for an optimal sterilization outcome. . For more information on our products and solutions, please visit .Our Textile Drying Oven offers exceptional quality within the Cooking & Baking Equipment category.By purchasing cooking & baking equipment in wholesale, you can enjoy cost savings through volume discounts, ensure consistent product quality across your operations, and access to a wide range of customization options to meet your needs.Additionally, ovens with custom solutions, including viewing windows, multiple temperature zones, and atmosphere control packages, are also available. . Our fan-assisted oven range facilitates air movement within the chamber, ensuring dry air around the sample which results in a fast-drying action. Moist air is continuously extracted from the . Other Quick Dry Tips. While the oven may be the most popular and quickest drying method, there are also other methods you can try to dry weed fast. And while some growers use a dehydrator in the drying process, while others place the weed upside down on a drying rack, below, we’ve included the easiest drying tips that anyone interested in .

Clause 8.5: Remove the test device from the oven, separate the multi-fibre patch or fabric patch (if used) from the test specimen, place the multi-fibre standard patch and the specimen on a metal screen, respectively, and condition for one night at an ambient temperature of (21±1)°C/(70±2)°F and humidity of (65±2)%. Honey powder is the perfect solution since we are making a dry rub. I like to use Honeeva or Soulbee honey powder. . Baking Dry Rub Chicken Wings In The Oven. Preheat the oven to 400°F (200°C). Then, place the dry-rubbed wings on a baking sheet lined with parchment paper or a wire rack in the sheet pan.

Perspirometer Sublimation Fastness Tester Inclind Flammability Tester Spray Tester Magnetic Stirrer Hot plate Dye Bath Circulatory Water Bath Electronic Balance Model AG-245 Dry Oven: Fibres,Yarn,Fibres Fibres,Yarn,Fibres Fibres,Yarn,Fibres Fibres,Yarn,Fibres Chemicals/Dyestuffs etc. . Solution to any problem related to weaving : Contact .

A precise oven is required. Included Accessories. AATCC weight with other parts in total 4.54kg(10lb) . placed in perspiration solution and then clamped on the perspirometer tester. Put it in a constant temperature in an oven, then dry it, and use a .

The PERSPIROMETER is designed for use in the determination of colourfastness of textiles to water, seawater and perspiration. STANDARDS BS 1006, BS EN 20105, ISO 105, AATCC 15, ISO 11642:2021 (E) This tester can conform to but is not limited to the standards above.

The test method is sew the sample and a standard lining fabric together, placed in perspiration solution and then clamped on the perspirometer tester. Put it in a constant temperature in an oven, then dry it, and use a gray card for rating to get the test result.

Cap Torque Tester tv shopping

thermoline laboratory drying oven

thermoline drying oven specifications

WEBRegister Form English . English; Contact Name: Mbsrgl. Login Name. 錯誤訊息:錯誤訊息錯誤訊息 Name. 錯誤訊息:錯誤訊息錯誤訊息 Password. 錯誤訊息:錯誤訊息錯誤 .

Dry Oven for Persptrometer solution|thermoline drying oven specifications